Smog Pump: 80-81 GM Various

These are rarer smog pumps found on late 70's .. 80 & 81 era GM vehicles with early emmissions needed. Normally noticed noise or out of round.. DO NOT EVER PRESSURE WASH A SMOG PUMP.. .. you will kill it.. seal it over and clean by hand..don't allow it to get water in it.

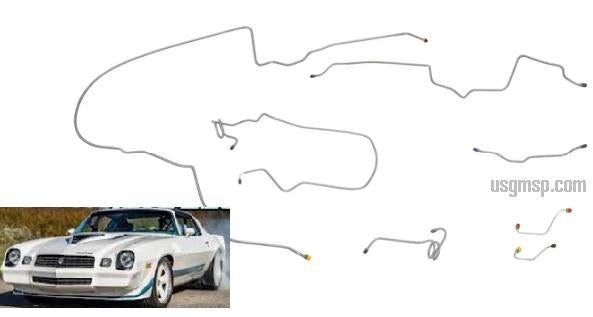

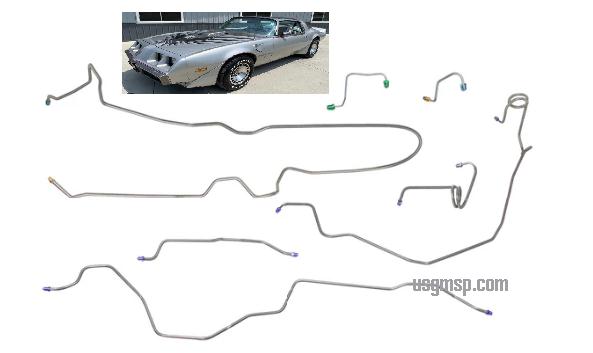

Take notice of the mounting pattern design.. don't just guess.. look at the images.. look at yours etc.. If unsure.. call us.. we are human and are based in Australia not just online.

NOT for 1980 Firebird Trans Am.

| CHEVROLET | CAMARO V6 | 1980-1981 |

| CHEVROLET | CAPRICE V6 | 1980-1981 |

| CHEVROLET | CORVETTE 305 & 350 V8 | 1980 |

| CHEVROLET | EL CAMINO V6 | 1979-1981 |

| CHEVROLET | IMPALA V6 | 1980-1981 |

| PONTIAC | BONNEVILLE V6 | 1981 |

| PONTIAC | CATALINA V6 | 1980-1981 |

| PONTIAC | FIREBIRD 301 & TURBO TA | 1981 |

| PONTIAC | GRAND LEMANS V6 | 1980-1981 |

| PONTIAC | GRAND PRIX V6 | 1981 |

Smog Pumps have a high fail rate too. They are NOT all just a plug and play Part for novices. Car dealers often ring after a trade-in has been detailed for a replacement..... Engine washed and filled with water etc.. NOT GOOD.

Just like you don't spray Alternators or wiper motors.

SO.. make sure to test your Air Pump Check Valve for proper operation. A defective check valve will allow harmful exhaust gases to enter and destroy a new Air Pump.

A NOTE ON SMOG PUMP CARE.... Preventing Smog Pump Seizures

Smog Pump failure is usually caused by Gasoline, exhaust fumes, oil, or water entering the unit contaminates the bearing grease causing bearing failure.

Before installing replacement unit, test check valve(s) for proper operation. Air should pass through valve only in one direction. These valves prevent exhaust gases from entering the unit. DO NOT install pump with a defective check valve. Check the PCV system for proper operation.

An inoperative or defective PCV system allows oil and gas fumes to enter Smog Pump, causing bearing failure.

Water contamination causes bearing corrosion, internal component damage, or housing failure. To help prevent this problem, carefully inspect all hoses, make sure fittings are secure, pump filters are not clogged, and the fan is not damaged. Be careful when washing the engine and, on low-mounted units, avoid driving through high water.

Cover pump when washing motor.

NOTE: Re-manufactured AIR PUMPS are tight when first supplied and require an average

500 mile run in period during which time noise can be expected from the new unit.

DO NOT OIL or Grease the unit.. do not wash or hose the pumps ever.

Couldn't load pickup availability

These are rarer smog pumps found on late 70's .. 80 & 81 era GM vehicles with early emmissions needed. Normally noticed noise or out of round.. DO NOT EVER PRESSURE WASH A SMOG PUMP.. .. you will kill it.. seal it over and clean by hand..don't allow it to get water in it.

Take notice of the mounting pattern design.. don't just guess.. look at the images.. look at yours etc.. If unsure.. call us.. we are human and are based in Australia not just online.

NOT for 1980 Firebird Trans Am.

| CHEVROLET | CAMARO V6 | 1980-1981 |

| CHEVROLET | CAPRICE V6 | 1980-1981 |

| CHEVROLET | CORVETTE 305 & 350 V8 | 1980 |

| CHEVROLET | EL CAMINO V6 | 1979-1981 |

| CHEVROLET | IMPALA V6 | 1980-1981 |

| PONTIAC | BONNEVILLE V6 | 1981 |

| PONTIAC | CATALINA V6 | 1980-1981 |

| PONTIAC | FIREBIRD 301 & TURBO TA | 1981 |

| PONTIAC | GRAND LEMANS V6 | 1980-1981 |

| PONTIAC | GRAND PRIX V6 | 1981 |

Smog Pumps have a high fail rate too. They are NOT all just a plug and play Part for novices. Car dealers often ring after a trade-in has been detailed for a replacement..... Engine washed and filled with water etc.. NOT GOOD.

Just like you don't spray Alternators or wiper motors.

SO.. make sure to test your Air Pump Check Valve for proper operation. A defective check valve will allow harmful exhaust gases to enter and destroy a new Air Pump.

A NOTE ON SMOG PUMP CARE.... Preventing Smog Pump Seizures

Smog Pump failure is usually caused by Gasoline, exhaust fumes, oil, or water entering the unit contaminates the bearing grease causing bearing failure.

Before installing replacement unit, test check valve(s) for proper operation. Air should pass through valve only in one direction. These valves prevent exhaust gases from entering the unit. DO NOT install pump with a defective check valve. Check the PCV system for proper operation.

An inoperative or defective PCV system allows oil and gas fumes to enter Smog Pump, causing bearing failure.

Water contamination causes bearing corrosion, internal component damage, or housing failure. To help prevent this problem, carefully inspect all hoses, make sure fittings are secure, pump filters are not clogged, and the fan is not damaged. Be careful when washing the engine and, on low-mounted units, avoid driving through high water.

Cover pump when washing motor.

NOTE: Re-manufactured AIR PUMPS are tight when first supplied and require an average

500 mile run in period during which time noise can be expected from the new unit.

DO NOT OIL or Grease the unit.. do not wash or hose the pumps ever.